Mesin Stone Crusher, a powerful machine used for crushing stones and rocks, plays a crucial role in various industries. Understanding the applicable scenarios and material handling capacity of this equipment is essential for optimizing its usage. By comprehending the specific scenarios where it excels and the capacity it can handle, businesses can make informed decisions to maximize productivity and efficiency.

Understanding Applicable Scenarios

In different industries, Mesin Stone Crushers find applications in various scenarios. Construction sites often require the crushing of materials to create a solid foundation or to produce aggregates for concrete. Quarrying and mining operations rely on mesin crusher batu crusher to extract and process raw materials from the earth efficiently. Additionally, in demolition projects, stone crushers play a vital role in breaking down structures and recycling materials.

Several factors influence the choice of Mesin Stone Crusher in different scenarios. Firstly, the required output capacity determines the size and type of crusher needed. The hardness and size of the materials to be crushed also impact the choice. Furthermore, environmental considerations, such as noise and dust control, may dictate specific requirements for stone crushers in certain scenarios.

Material Handling Capacity of Mesin Stone Crusher

Material handling capacity refers to the ability of a stone crusher to process and handle a certain amount of material within a given time frame. It is a crucial aspect that determines the overall efficiency of the crushing process. Factors affecting material handling capacity include the design and specifications of the crusher, the power and efficiency of the motor driving the crusher, and the feeding mechanisms and conveyor systems employed.

Evaluating Material Handling Capacity

To ensure that a Mesin Stone Crusher meets the material handling requirements of a particular scenario, careful evaluation is necessary. Determining the required material handling capacity involves calculating the average feed rate, analyzing the desired product size distribution, and considering the overall production targets. These assessments help in selecting a mesin pemecah batu kerikil with the appropriate capacity.

Testing and verifying the material handling capacity is also crucial. Pilot projects and field tests can provide valuable insights into a crusher’s performance. Monitoring and adjusting the crusher operation based on real-time data further enhances the efficiency and safety of the crushing process.

Optimizing Material Handling Capacity

To optimize material handling capacity, it is essential to focus on improving crusher performance and productivity. Regular maintenance and inspection ensure that the crusher operates at its peak efficiency. Upgrading and optimizing crusher components, such as the crushing chamber and liners, can also enhance its capacity. Furthermore, implementing automation and control systems can streamline operations and increase productivity.

In addition to improving the crusher itself, enhancing material handling processes can contribute to maximizing capacity. Efficient feeding mechanisms and proper material flow management prevent bottlenecks and ensure continuous feed. Effective conveyor systems facilitate the transportation of material, further enhancing overall productivity. Additionally, utilizing screening and sorting technologies can help segregate materials efficiently, optimizing the crushing process.

Case Studies: Mesin Stone Crusher in Different Scenarios

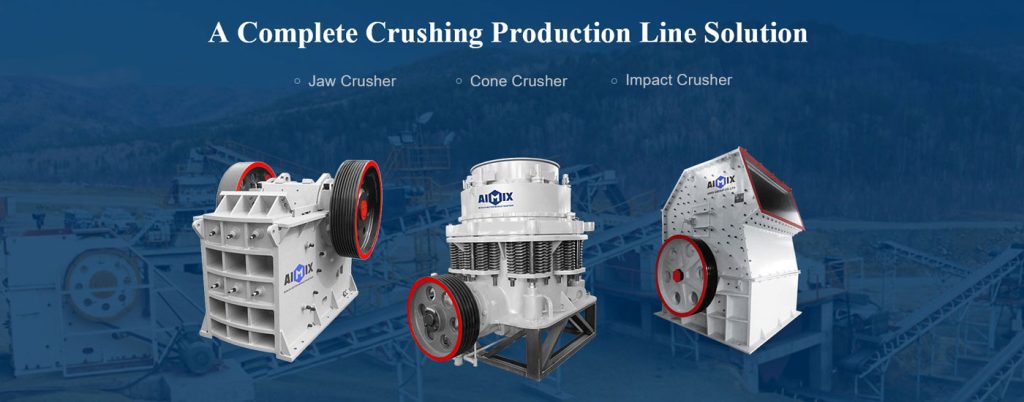

Examining case studies of Mesin Stone Crusher applications in different scenarios provides practical insights into its capabilities. In construction sites, stone crushers have proven to be instrumental in achieving project goals by efficiently processing materials. Quarrying and mining operations benefit from the reliability and high capacity of stone crushers, enabling the extraction and processing of large quantities of raw materials. Moreover, in demolition projects, AIMIX stone crushers aid in breaking down structures and recycling materials, promoting sustainability.

Understanding the applicable scenarios and material handling capacity of Mesin Stone Crushers is crucial for businesses seeking to maximize efficiency and productivity. By comprehending the specific scenarios where these crushers excel and the capacity they can handle, informed decisions can be made during the selection process. This knowledge allows for the optimization of material handling processes, resulting in enhanced performance and improved overall productivity. With the right understanding and utilization of alat pemecah batu besar, businesses can achieve their goals effectively and efficiently.