Asphalt, a widely used material for constructing roads, driveways, and pavements, plays a crucial role in modern infrastructure. However, traditional asphalt production processes have been associated with various environmental challenges. These challenges include air pollution, greenhouse gas emissions, and the depletion of natural resources. In recent years, the need for environmentally friendly solutions has become paramount, prompting the development of innovative technologies, such as the environmentally friendly asphalt mixing plant.

Reduced Emissions

One of the primary reasons asphalt mixing plants are considered environmentally friendly is their ability to significantly reduce harmful emissions compared to conventional jual asphalt mixing plant baru. Traditional asphalt plants release large amounts of volatile organic compounds (VOCs), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) into the atmosphere during the production process. These emissions contribute to air pollution, smog formation, and adverse health effects.

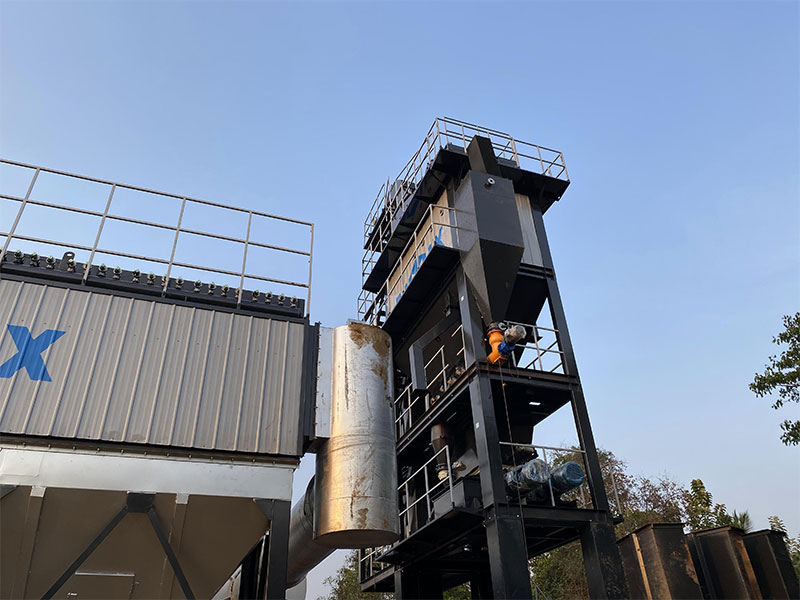

Environmentally friendly asphalt mixing plants are equipped with advanced emission control systems, including baghouses, wet scrubbers, and cyclone collectors. These technologies capture and filter harmful emissions, ensuring that only clean air is released into the environment. By utilizing such technologies, the environmental impact of asphalt production is greatly reduced, making these plants more sustainable and responsible.

Energy Efficiency

Another factor that makes asphalt mixing plants environmentally friendly is their improved energy efficiency. Traditional aspal mixing plant mini often require significant amounts of energy to heat the aggregates and produce hot mix asphalt. This high energy demand leads to increased greenhouse gas emissions and contributes to global warming.

In contrast, modern asphalt mixing plants are designed with energy-saving features, such as energy-efficient burners, thermal insulation, and advanced control systems. These innovations optimize energy consumption, reducing the overall carbon footprint of the asphalt production process.

Use of Recycled Materials

Environmentally friendly asphalt mixing plants embrace the concept of sustainability by incorporating recycled materials into the production process. Conventional asphalt plants rely primarily on virgin aggregates, which involve mining and extraction, leading to habitat destruction and resource depletion.

However, environmentally friendly asphalt mixing plants can use reclaimed asphalt pavement (RAP) and recycled asphalt shingles (RAS) as part of the asphalt mix. RAP and RAS are recycled materials obtained from old asphalt pavements and roofing shingles. Incorporating these materials not only reduces waste in landfills but also conserves natural resources and reduces the demand for new aggregates.

Low Emission of Greenhouse Gases

The reduction of greenhouse gas emissions is a crucial aspect of making any industrial process environmentally friendly. Traditional asphalt production releases substantial amounts of carbon dioxide (CO2) and other greenhouse gases due to the energy-intensive nature of the process.

To combat this, environmentally friendly asphalt mixing plants adopt sustainable practices to minimize greenhouse gas emissions. As mentioned earlier, energy-efficient technologies play a significant role in achieving this goal. Additionally, the use of recycled materials, as well as the implementation of warm-mix asphalt technology, further decreases the carbon footprint of the asphalt production process.

Warm-mix asphalt technology allows for the production of asphalt at lower temperatures compared to conventional hot-mix asphalt. This results in reduced energy consumption and lower emissions of greenhouse gases, making the process more environmentally friendly.

Noise Reduction

Traditional asphalt plants can be noisy due to the continuous operation of heavy machinery and equipment. The noise pollution generated by these plants can disrupt nearby communities and disturb local wildlife.

Environmentally friendly asphalt mixing plants are designed with noise reduction in mind. Innovations like noise barriers, insulated enclosures, and quieter equipment contribute to minimizing noise levels during asphalt production. This makes this pabrik aspal more compatible with residential areas and environmentally sensitive regions.

Conclusion

The transformation of the asphalt mixing plant into an environmentally friendly equipment represents a significant step forward in mitigating the environmental impact of road construction and maintenance. By embracing emission reduction technologies, improving energy efficiency, incorporating recycled materials, and reducing greenhouse gas emissions, these plants exemplify the importance of sustainable practices in the construction industry.

As environmental awareness continues to grow, the demand for environmentally friendly asphalt mixing plants is expected to rise. Governments, construction companies, and stakeholders are recognizing the benefits of investing in these eco-friendly solutions to pave the way towards a greener and more sustainable future.